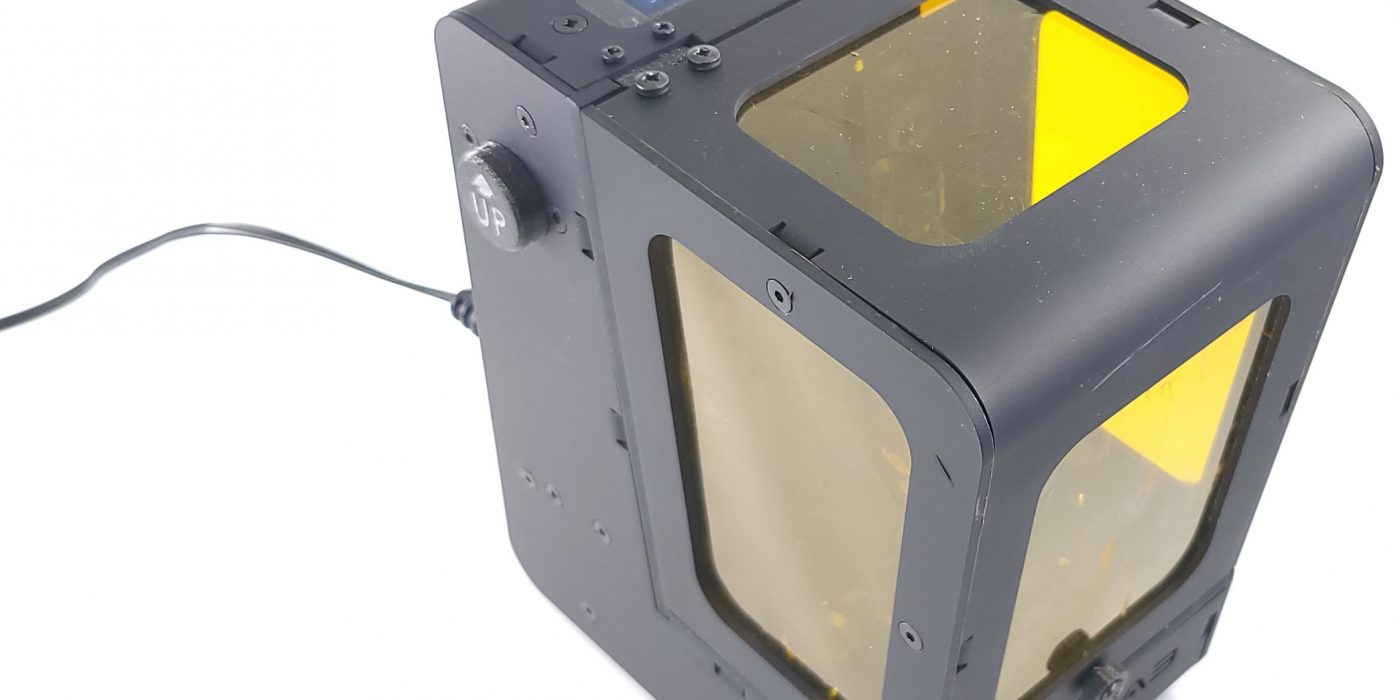

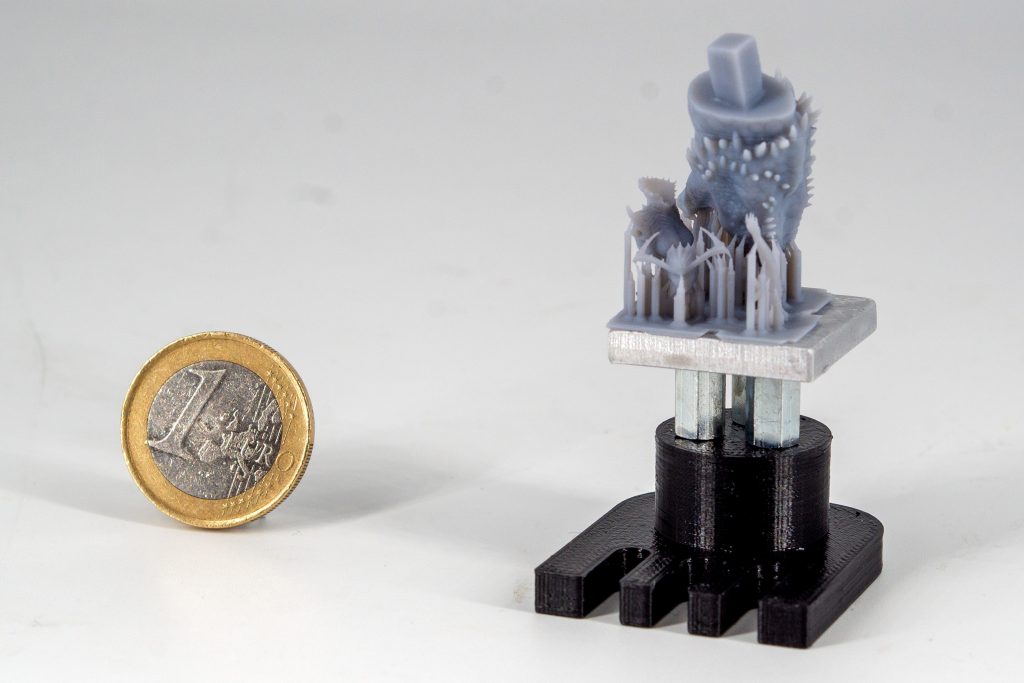

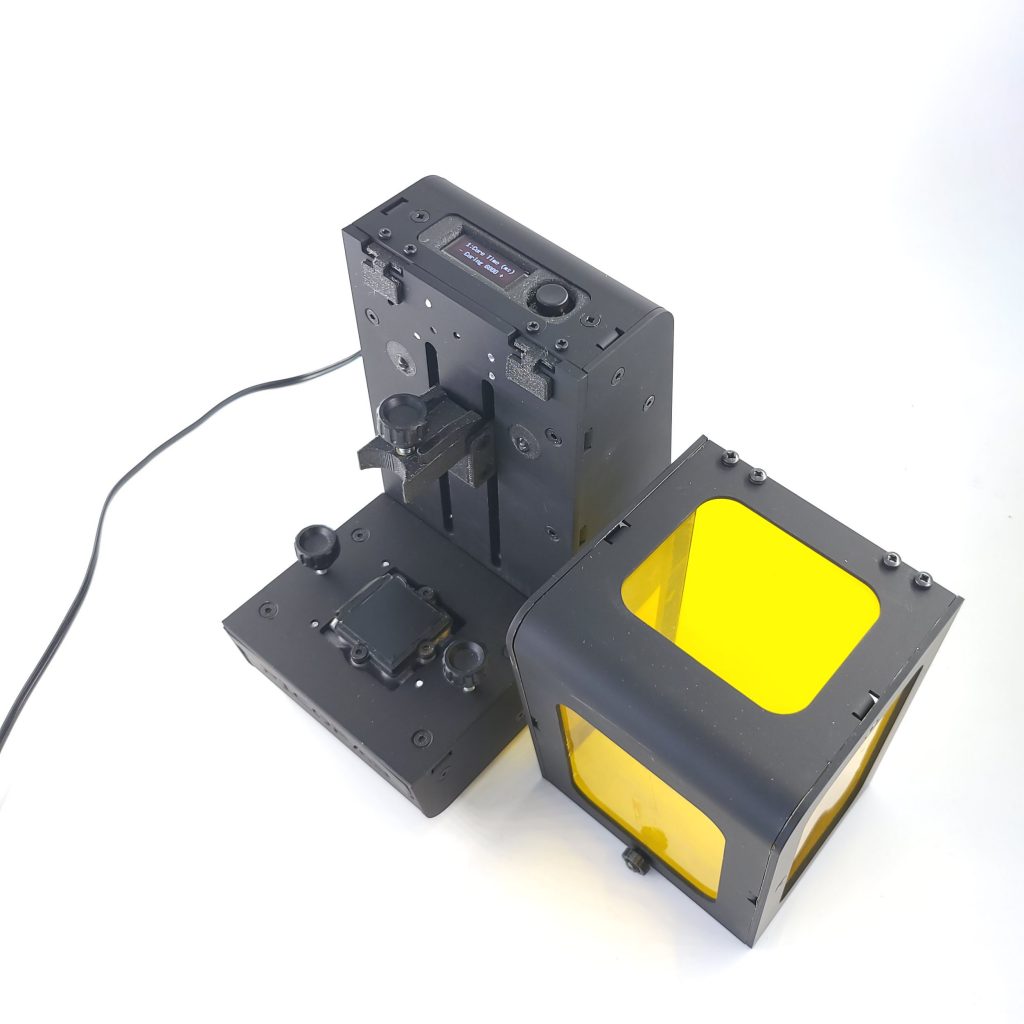

In 2020 I developed a micro LCD printer. It features an tiny light engine I designed that works very well at 405nm and that I started to test at 385nm too. A working micro cleaning station has also been developed as a working prototype, with 2 magnet stirrers, RPM feedback, individual control. I tested with layer height of 50 and 25 microns, thanks to an integrated miniaturized linear actuator I developed.

The focus of the Picofab is to be a 3D Printer for dental crowns and bridges up to 4 elements; it can be used also to create parts in castable resin for jewelry artisans and studios.

Using this 3D printer for small jobs could allow the user to use expensive mills / 3D Printers only for more complex jobs, maximizing the efficiency of them.

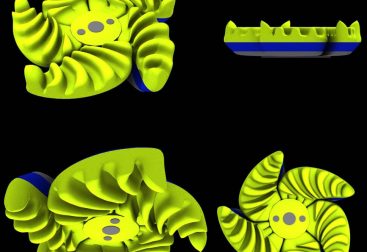

Below some of the may 3D Printing tests I did, including castable resin for jewelry and dental resins for crowns and bridges. More details can also be found for the PicoFab, a compact 3D printer for dental crowns and bridges, and castable jewelry parts, on https://www.facebook.com/picoFAB